WearTuf 400 Abrasion Resistant Steel Plates

resistance with outstanding weldability and cold forming capabilities.

Classification :

Key Word :

WearTuf 400 Abrasion Resistant Steel Plates

PRODUCT DETAILS

Product Introduction

Characteristics

WearTuf 400 is a fully martensitic Q&T abrasion resistant steel plate, having a hardness of average 400 Brinell. WearTuf 400 is a versatile wear plate that combines abrasion resistance with outstanding weldability and cold forming capabilities. The high impact toughness grants a very good crack resistance of the steel during fabrication and in service.

Dimensions

WearTuf 400 is supplied in the thickness rage of 4.0 - 50.0 mm and in the plate width of 900 – 3 100 mm. Supplied plate length from 4 000 to 18 000 mm.

Impact toughness

Typical 45J/-40°C (-40°F)

The impact toughness is given as absorbed energy at temperature, being the average of three full size Charpy-V test samples in longitudinal direction to rolling, according to EN ISO 148-1.

Hardness guarantee

Surface hardness:370-430 Brinell

Guaranteed hardness range, measured on a milled surface at a depth of 0.5 – 2.0 mm below the plate surface, according to ISO EN 6506-1.

Min center hardness:

Plate thickness ≤ 20mm: min 370 Brinell

Plate thickness > 20mm: 95% of min guaranteed surface hardness.

Applications

WearTuf 400 has found its application base among the traditional earth moving, mining and transport equipment, such as buckets, dumpers, tippers, crushers, hammers, conveyors and other mineral feeding systems. Being supplied in the thin and wide dimension range, WearTuf 400 also focuses on light weight wear design concepts and applications.

Ultrasonic testing

All plates delivered meets the Class E1, S1 requirement, according to EN 10 160.

Delivery condition

WearTuf 400 is delivered in the as quenched (Q) condition, and when found necessary in the condition of quenched and tempered (QT).

The plates are delivered with sheared or thermally cut edges.

Tolerances

The thickness tolerances of WearTuf 400 meets and exceeds the thickness tolerance of EN 10 029

Class A . Tolerances on shape, length, and width meets the requirements of EN 10029. Flatness tolerances conforms to EN 10 029 Class S or closer.

Surface condition and properties

The delivered surface finish meets and exceeds that of EN 10163-2 Class A, Subclass 3.

The plates will be delivered as shot painted, using a low zinc silicate corrosion protective shop primer. Plates can also be delivered as unpainted.

Heat Treatment

Since the properties in the as delivery condition cannot be retained after exposure at service temperatures above 250°C, WearTuf 400 is not intended for any further heat treatment.

Processing performance

1) Bending,

2) Welding,

3) Cutting

4) Machining

Technical Data

Chemical Composition

Ladle analysis: The steel is grain refined and fully killed, wt%

| Thickness (mm) |

C max |

Si max |

Mn max |

P max |

S max |

Cr max |

Ni max |

Mo max |

B max |

CEV Typical |

CET Typical |

| 4.0 – 12.0 | 0.18 | 0.50 | 1.50 | 0.025 | 0.010 | 0.40 | 0.10 | 0.20 | 0.004 | 0.36 | 0.25 |

| 12.1 – 25.0 | 0.20 | 0.50 | 1.50 | 0.025 | 0.010 | 0.60 | 0.15 | 0.25 | 0.004 | 0.45 | 0.29 |

| 25.1 – 40.0 | 0.20 | 0.50 | 1.50 | 0.025 | 0.010 | 1.00 | 0.20 | 0.35 | 0.004 | 0.56 | 0.33 |

| 40.1 – 50.0 | 0.21 | 0.7 | 1.50 | 0.025 | 0.010 | 1.20 | 0.25 | 0.50 | 0.004 | 0.62 | 0.35 |

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40

Mechanical Properties

| Yield strength Rp0.2 |

Tensile strength Rm |

Elongation A5 |

| 1000 MPa | 1250 MPa | 10% |

Factory appearance and appearance

With strong financial strength, we have set up large factories and warehouses in more than 10 cities across the country, with a stock of more than 100000 tons, saving customers procurement time, ensuring customers' production cycle and product quality, and being the quality partner of end customers.

Factory appearance and appearance

1. Samples may be provided by the seller and freight borne by the buyer.

2. We have full stock,and can deliver within short time. Many styles for your choices.

3. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

4. All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

5. We have many years of experience in manufacturing and selling steel and we cherish every order from our honor.

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

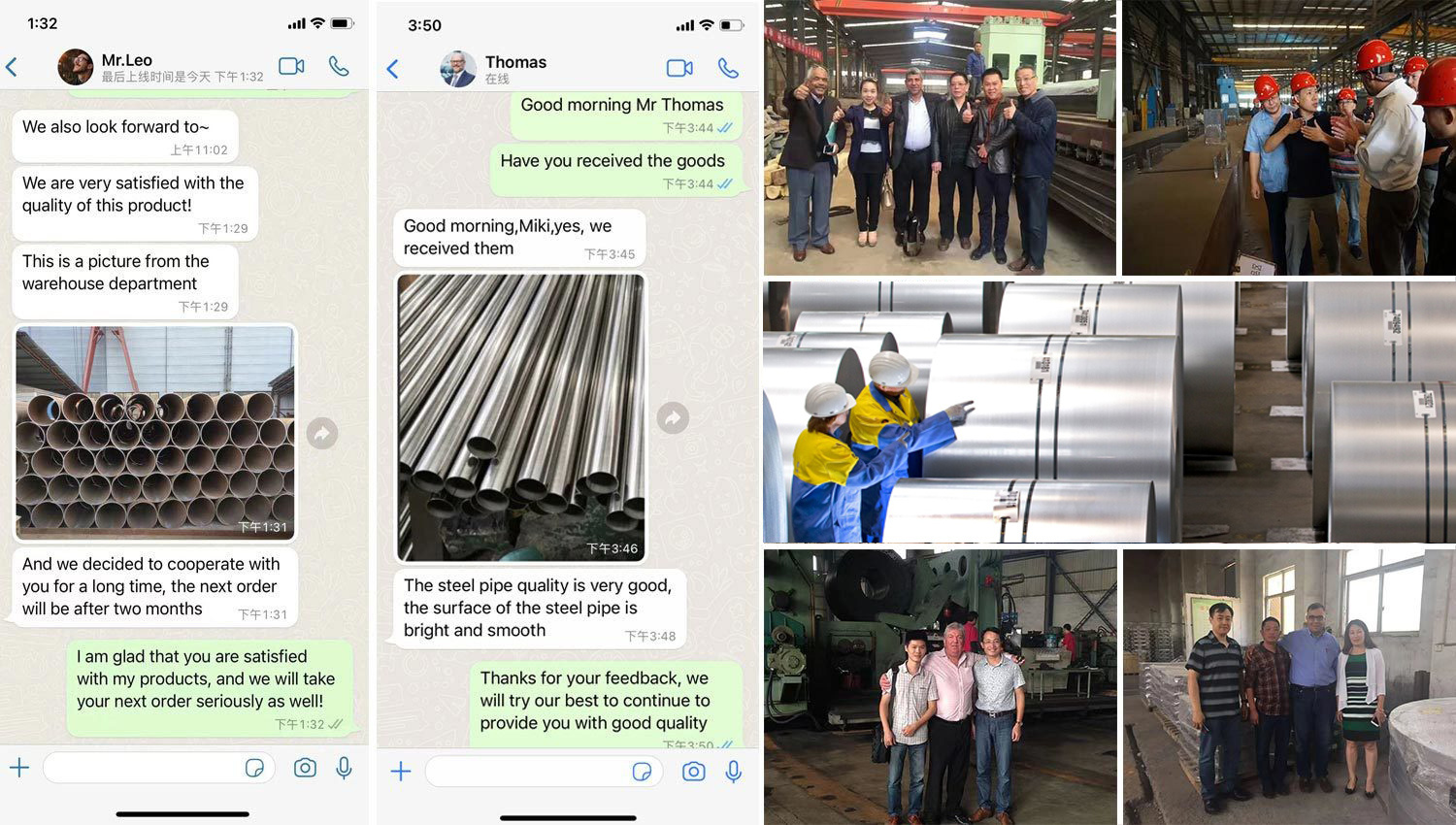

Customer Visit Feedback

With 30 years of experience in R&D and production of high-quality steel, we have been selected as one of China's top 500 enterprises for 15 consecutive years. With strong financial strength, we have set up large factories and warehouses in more than 10 cities across the country, with a stock of more than 100000 tons

Honor

The company has adhered to the principle of quality first and service-oriented for many years, and has provided high-quality steel for key national projects such as steel structure engineering, highway and railway construction, hydropower stations, mines, and plant renovations.

COOPERATIVE PARTNER

FAQ

Q3 : It's my first time to import steel products, can you help me with it?

A : Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q5:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Q6:What kind of work does your company do?

A:Our company is a professional manufacturer. We mainly produce stainless steel plate/coil/round rod, carbon steel plate/coil,galvanized plate/coil, PPGI coil, roofing sheet and so on.

Q1:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q2 : What product information do I need to provide?

A : Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q7;What are the advantages of your company?

We have international advanced production equipment, large factory buildings, strong company strength, perfect products and reliable quality。

Q8: Are you a factory or trading company?

A;We are a factory specializing in the production of steel

RELATED PRODUCTS

GET A FREE QUOTE