-

ABOUT USThe company can also deliver goods directly from the steel plant according to customer needs, thus saving landing costs and reducing costs and prices. In line with the service purpose of moving house and considering the needs

-

PRODUCT CENTERWith strong financial strength, we have set up large factories and warehouses in more than 10 cities across the country, with a stock of more than 100000 tons, saving customers procurement time, ensuring customers' production

-

NEWSWith strong financial strength, we have set up large factories and warehouses in more than 10 cities across the country, with a stock of more than 100000 tons, saving customers procurement time, ensuring customers' production

PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

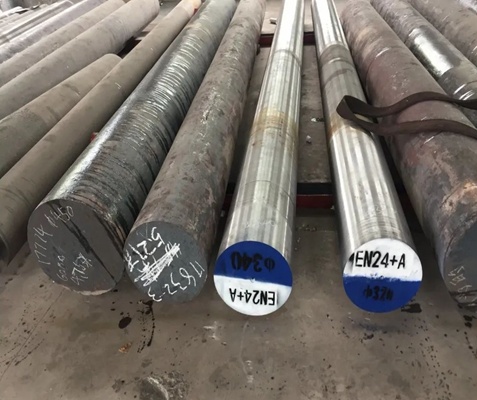

W6Mo5Cr4V2Co5(M35) hot rolled steel round bars

W18Cr4V hot rolled steel round bars

REQUEST YOUR CUSTOMISED PROJECT

Speak With Our Experienced Consultants To Learn How

BAOSTEEL GROUP

Tel : +86-15315575332

Email : phl@zgbaogangsteel.com

WhatsApp:+86-15315575332

Address : Minlong steel trading market , Qingdao ,China

GET A FREE QUOTE

Copyright @ 2023 Baosteel (Shandong) Group Co., Ltd. All Right Reserved. Seo Tags BUSINESS LICENSE