PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

Hot-dip galvanizing is a process of coating steel

with a thin zinc layer, which serves as a barrier between the steel

and the environment.

The finish is applied by passing the steel through

a molten bath of zinc at a high temperature.

VIEW MORE +

with a thin zinc layer, which serves as a barrier between the steel

and the environment.

The finish is applied by passing the steel through

a molten bath of zinc at a high temperature.

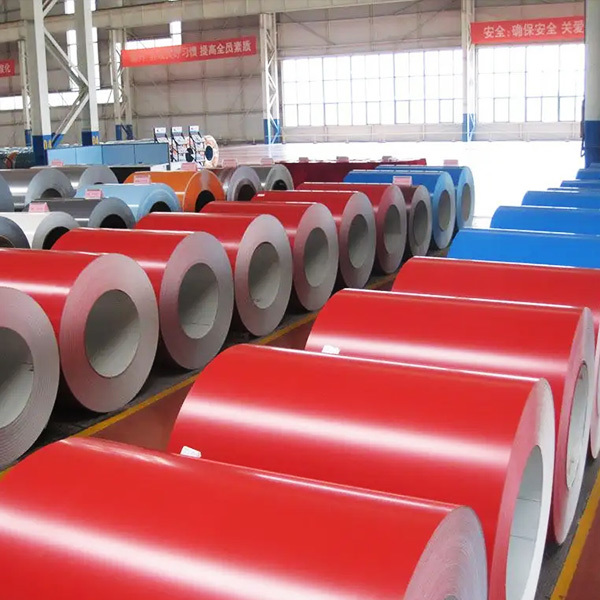

DX54D prepainted galvanized steel /ppgi/prime steel coil/steel sheet

Prepainted galvalume steel coils, is also named

color coated galvanized steel coil,

PPGL coil, it has superior corrosion resistance,

oxidation resistance and weldability are widely used in construction, etc.

VIEW MORE +

color coated galvanized steel coil,

PPGL coil, it has superior corrosion resistance,

oxidation resistance and weldability are widely used in construction, etc.

SGLCC 0.35mm Hot Dipped Galvanized Corrugated Steel roof sheet

Pressed corrugated steel sheet (roofing sheet) refers to the steel sheet formed by cold pressing or cold rolling.

The steel sheet is made of coloured steel sheet, galvanized steel sheet, stainless steel sheet, aluminium sheet,

anticorrosive steel sheet or other thin steel sheet. The profiled steel sheet has the characteristics of light weight,

high strength, low price, good seismic performance, fast construction and beautiful appearance.The corrugated

metal is a good building material, mainly used for guardrail, floor and other buildings, such as airport terminal,

railway station, stadium, concert hall, grand theatre, etc. According to different application requirements, the

profiled steel sheet can be pressed into a wave type, a T type, a V type, a rib type and the like.

VIEW MORE +

The steel sheet is made of coloured steel sheet, galvanized steel sheet, stainless steel sheet, aluminium sheet,

anticorrosive steel sheet or other thin steel sheet. The profiled steel sheet has the characteristics of light weight,

high strength, low price, good seismic performance, fast construction and beautiful appearance.The corrugated

metal is a good building material, mainly used for guardrail, floor and other buildings, such as airport terminal,

railway station, stadium, concert hall, grand theatre, etc. According to different application requirements, the

profiled steel sheet can be pressed into a wave type, a T type, a V type, a rib type and the like.

CGCH Galvanized steel Coil/Sheet PPGI and PPGL

Our business scope: Color coated steel coils/sheets,

GI / GL (with Anti-finger) Cold roll, Corrugated sheets /

Roofing sheets, embossed coils and ect.

The company has passed the SGS,BV,ISO9001 Quality Management System certification.

VIEW MORE +

GI / GL (with Anti-finger) Cold roll, Corrugated sheets /

Roofing sheets, embossed coils and ect.

The company has passed the SGS,BV,ISO9001 Quality Management System certification.

Q195 PPGI corrugated roofing sheet

corrugated roofing and wall cladding profile,

which offers flexibility of design for Roof and

Wall cladding applications in Industrial,

Commercial, Residential and Public building.

VIEW MORE +

which offers flexibility of design for Roof and

Wall cladding applications in Industrial,

Commercial, Residential and Public building.

CGCC color coated corrugated roof sheet

The purity of the coating is high, so the corrosion resistance of the

coating at the same thickness is better than that of hot-dip galvanized products.

According to the test, under the same conditions, according to the

American standard (ASTMB 114), the red rust resistance time of a micron

coating is 12 hours for electrogalvanizing and less than 10 hours for hot

galvanizing. However, it is very difficult to obtain a thick electro-galvanized

coating (large power consumption, high cost, and technical difficulty).

As a color-coated substrate, the use of electro-galvanized is also

mainly applied to home appliances, steel furniture, doors and windows, and the like.

VIEW MORE +

coating at the same thickness is better than that of hot-dip galvanized products.

According to the test, under the same conditions, according to the

American standard (ASTMB 114), the red rust resistance time of a micron

coating is 12 hours for electrogalvanizing and less than 10 hours for hot

galvanizing. However, it is very difficult to obtain a thick electro-galvanized

coating (large power consumption, high cost, and technical difficulty).

As a color-coated substrate, the use of electro-galvanized is also

mainly applied to home appliances, steel furniture, doors and windows, and the like.